الروبوتات في حل المسبك

الروبوتات في حل المسبك:

1، زيادة الكفاءة: يمكن للروبوتات في المسابك تحسين الكفاءة بشكل كبير من خلال أتمتة المهام مثل معالجة المواد، والصب، والتشطيب. يمكن للروبوتات العمل بوتيرة ثابتة دون انقطاع أو تعب، مما يؤدي إلى إنتاج أسرع وتقليل أوقات الدورات.

2، تحسين سلامة العمال: يمكن أن تكون عمليات المسبك خطيرة، مما يعرض العمال لدرجات حرارة عالية، والمعدات الثقيلة، والمواد الخطرة. يمكن أن يساعد استخدام الروبوتات في صناعة المسابك في تقليل هذه المخاطر من خلال التعامل مع المهام الخطيرة، مما يقلل من احتمالية وقوع حوادث وإصابات للعمال البشريين.

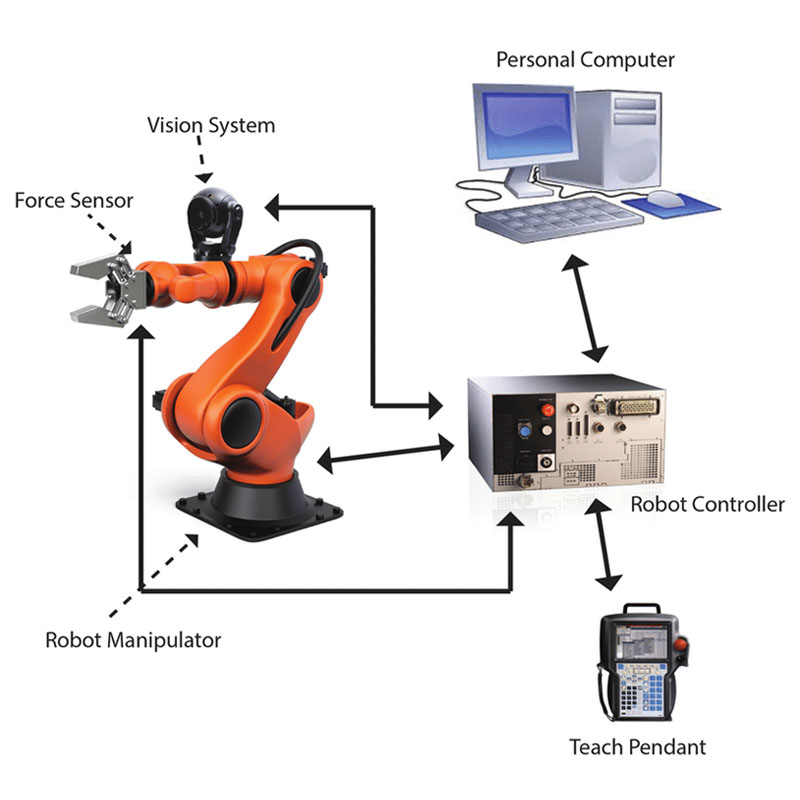

3، تعزيز الدقة والدقة: يمكن للروبوتات في المسابك أداء المهام بمستوى عالٍ من الدقة والدقة. يمكنهم صب المعدن المنصهر بدقة في القوالب، والتعامل مع الأجزاء ووضعها باستمرار، وتنفيذ مهام التشطيب المعقدة. يؤدي هذا إلى تحسين جودة الصب ويقلل من مخاطر العيوب أو عدم الاتساق.

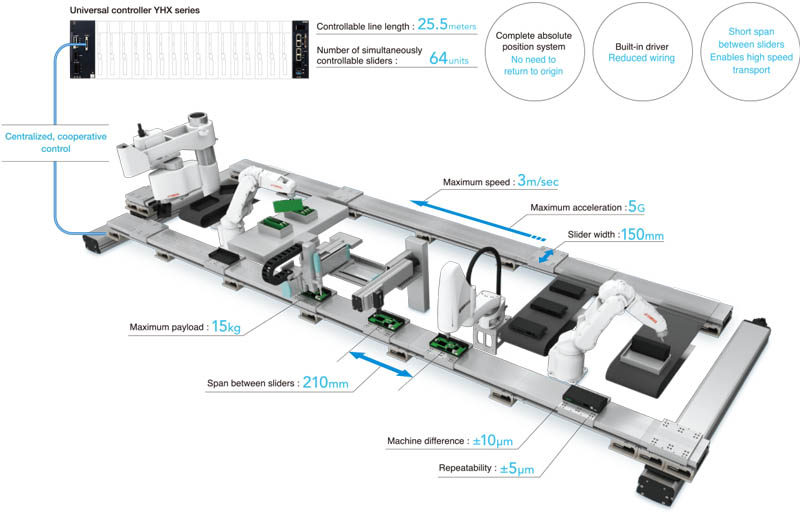

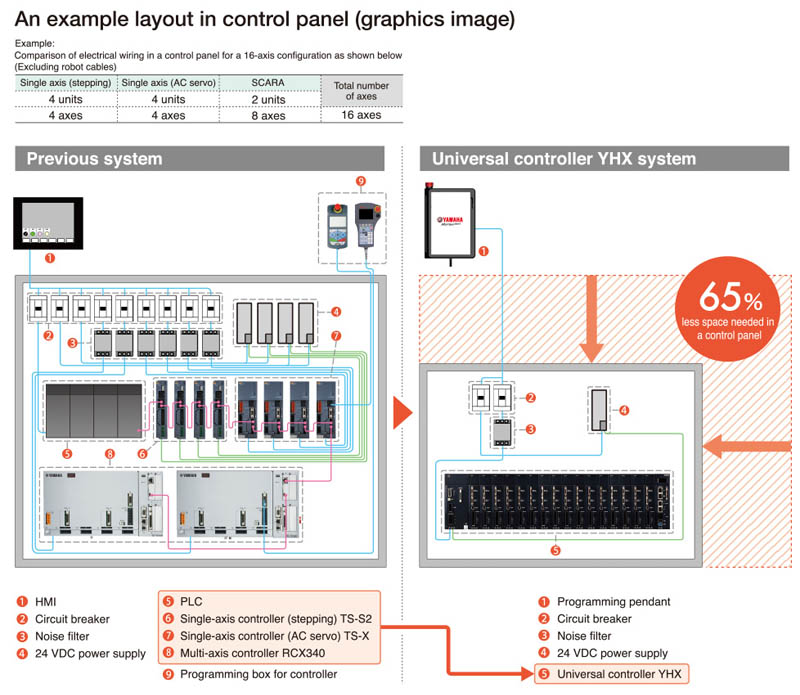

يرجى الاتصال بنا للحصول على المعلمات التقنية التفصيلية.

الروبوتات في حل المسبك:

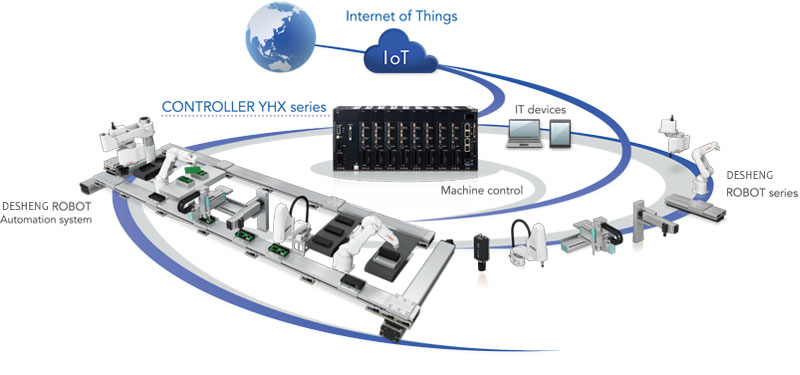

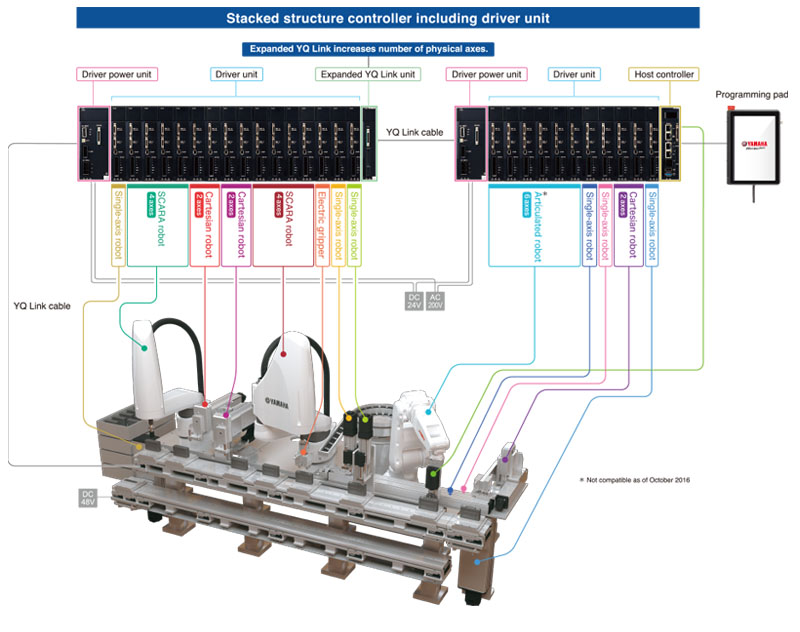

أحدثت الروبوتات في تطبيقات المسبك ثورة في الصناعة التحويلية. الروبوتات في حل المسبك في شركتنا يستطيع وفر 92% من التكلفة من دورية مأهولة. يرجى الاتصال بنا للحصول على المعلمات التقنية التفصيلية. تُستخدم الروبوتات في مهام مثل الصب والقولبة والتشطيب، مما يقلل من مشاركة الإنسان ويزيد الكفاءة والدقة. يمكنها تحمل الظروف القاسية، بما في ذلك درجات الحرارة العالية والغبار، مما يضمن جودة إنتاج ثابتة. تعمل الروبوتات أيضًا على تعزيز السلامة من خلال أداء المهام الخطيرة، وتقليل الإصابات في مكان العمل. بالإضافة إلى ذلك، فهي قابلة للبرمجة ويمكن تخصيصها لتلبية متطلبات الإنتاج المحددة. تقلل تقنية الأتمتة هذه من تكاليف التشغيل وتعزز الإنتاجية، مما يجعلها جزءًا لا يتجزأ من المسابك الحديثة.