شركة أب مسبك روبوت الحل

حل روبوت مسبك ABB :

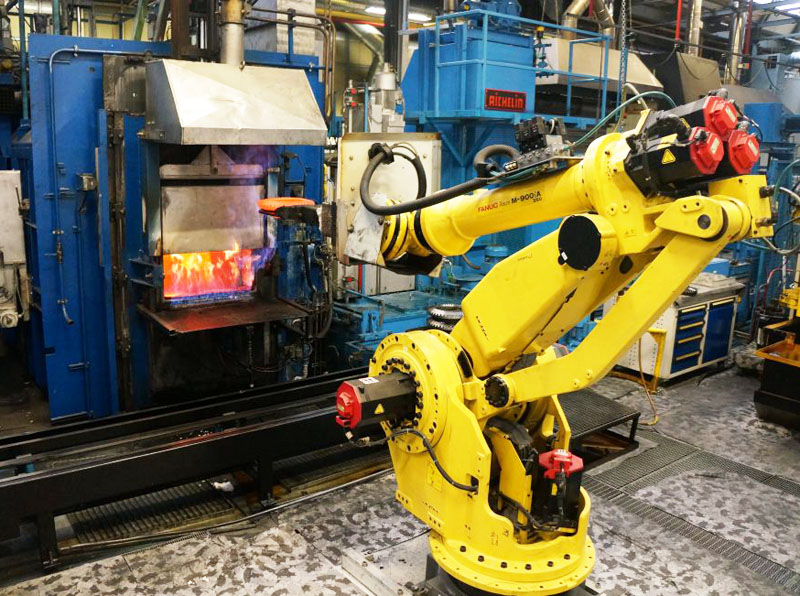

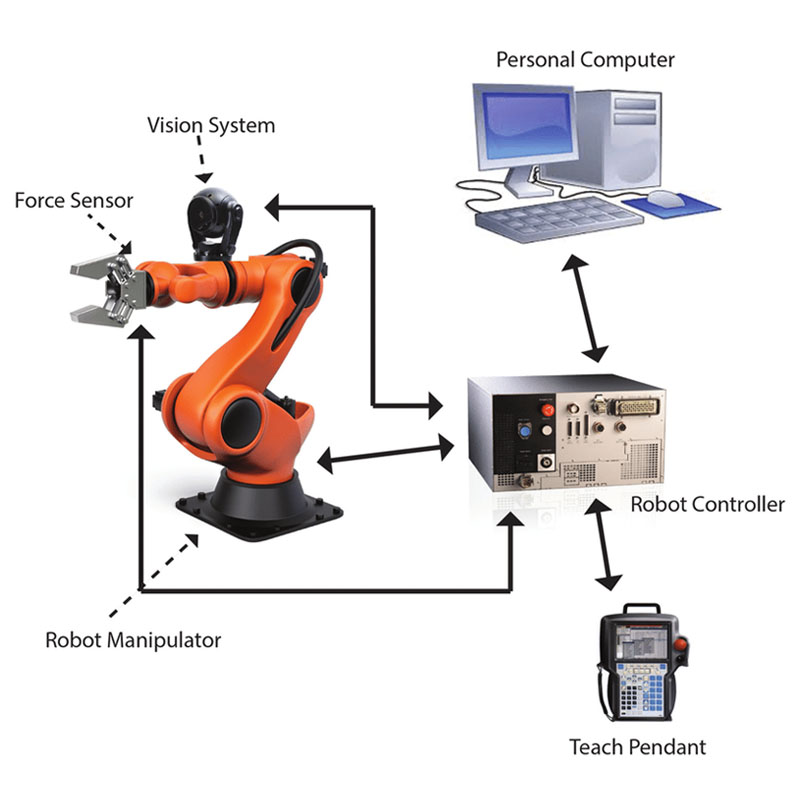

1،قدرات الأتمتة المتقدمة: تم تجهيز روبوتات مسبك ABB بقدرات أتمتة متقدمة، مما يسمح لها بالتعامل مع المهام المعقدة بدقة ودقة. يمكنهم أداء مهام مثل صب المعدن المنصهر، والتعامل مع المكونات الثقيلة، والتعامل مع القوالب بسهولة.

2، تحسين سلامة العمال: تساعد روبوتات المسبك ABB على تقليل المخاطر التي يتعرض لها العمال البشريون في بيئات المسبك الخطرة. يمكنهم التعامل مع المهام في درجات الحرارة القصوى، والعمل في الأماكن الضيقة، والتعامل مع الأحمال الثقيلة، مما يقلل من احتمالية وقوع حوادث وإصابات.

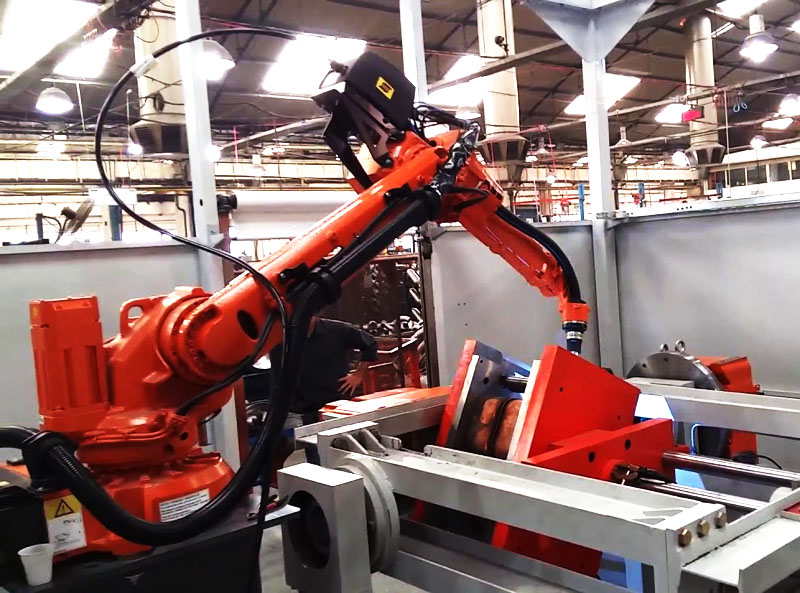

3، تعزيز الإنتاجية والكفاءة: تعمل روبوتات المسبك ABB على تحسين الإنتاجية بشكل كبير في عمليات المسبك. يمكنهم العمل بشكل مستمر دون انقطاع، مما يؤدي إلى زيادة معدلات الإنتاج وتقليل أوقات الدورات. تسمح حركاتها السريعة والدقيقة بسير عمل فعال ومحسن في المسبك.

يرجى الاتصال بنا للحصول على المعلمات التقنية التفصيلية.

حل روبوت مسبك ABB :

تُستخدم ABB Foundry Robots بشكل أساسي في الصناعات لمهام مثل معالجة المواد، وصيانة الماكينات، والصب، وصب القوالب، واللحام البقعي. وهي مصممة لتحمل البيئات القاسية وارتفاع درجة الحرارة. تعمل هذه الروبوتات على زيادة الإنتاجية وتحسين الجودة وتعزيز السلامة في مكان العمل. كما أنها تستخدم في صناعة السيارات لمهام مثل التجميع والطلاء واللحام. كما أن روبوتات ABB Foundry قادرة أيضًا على أداء مهام أكثر تعقيدًا، مثل الطباعة ثلاثية الأبعاد، بدقة وإتقان. وهي مصممة لتكون مرنة ومتعددة الاستخدامات للتكيف مع مجموعة متنوعة من التطبيقات الصناعية.